T304 grade stainless has excellent welding and formability characteristics and is one of the most utilized stainless steels. 304 strip coil is an extra low carbon grade with a 0.03% max carbon content that eliminates carbide precipitation due to welding. 304 stainless steel strip, coil, and sheet can be used for a variety of applications.

Product Parameters

| Item | Stainless Steel 304 Strip Coils(Hot rolled, cold rolled) |

| Standard | JIS, AISI, ASTM, GB, DIN, EN, etc |

| Grade | ASTM A240, ASME SA240 |

| Thickness | 0.025 to 3 mm and as per Customer Requirement |

| Width | 3 mm to 2000 mm and as per Customer Requirement |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Hardness | Full Hard, Rolled, 1/2 hard or Half Hard, 1/4 Hard or Quarter Hard, 3/4 Hard, Soft or Annealed- Pickled |

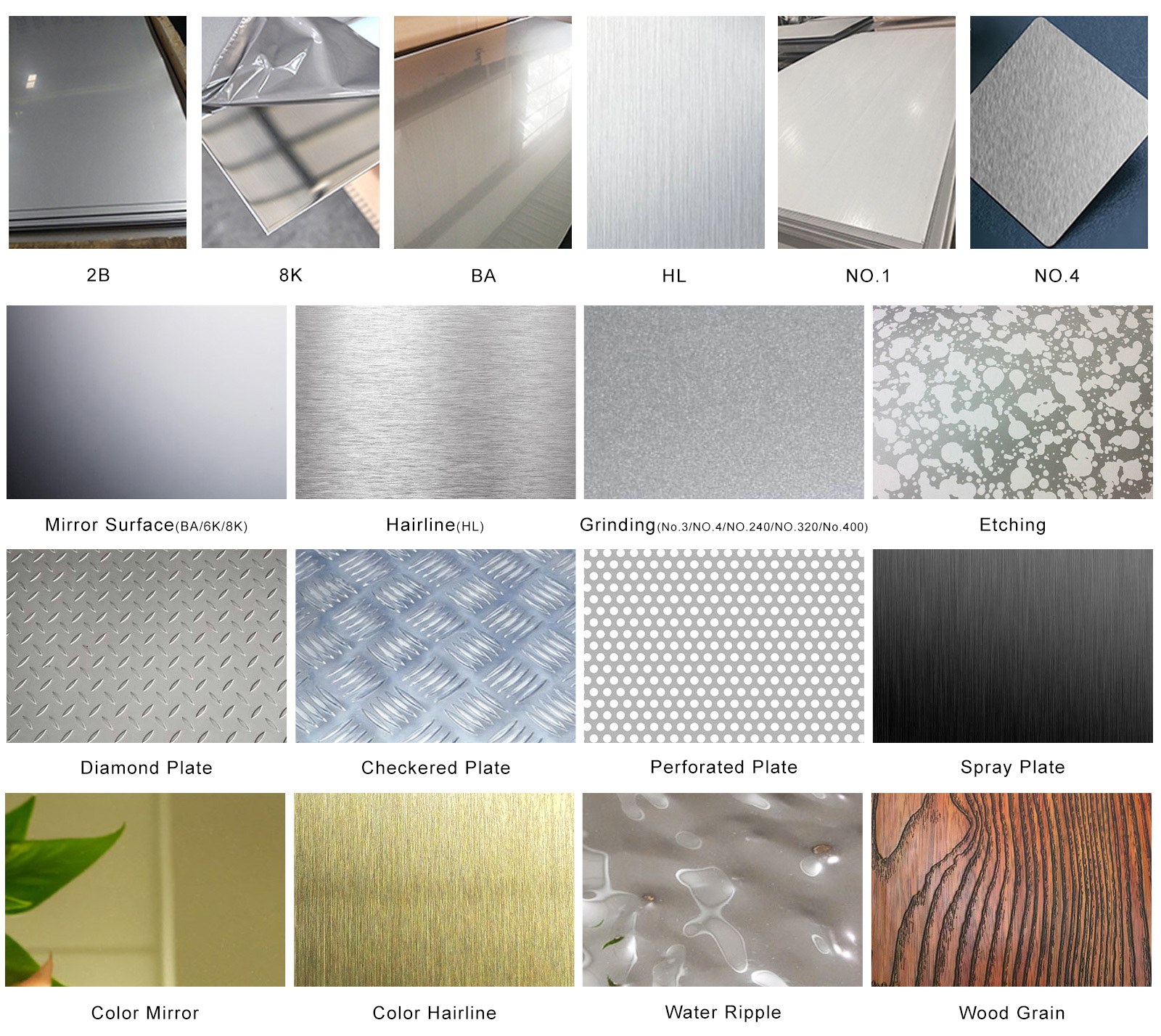

| Surface | Cold rolled (CR), Hot rolled (HR), Galvanized, Plastic Coated, SATIN, 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc |

| Brand | Indian Origin, European Origin, Japanese Origin, US Origin, Korea Origin, Thailand Origin, Taiwan Origin |

| Manufacturer | POSCO, Aperam, Jindal Stainless, DKC Korea, Thyssenkrup, Baosteel, TISCO, Arcelor Mittal, VDM, Nippon Metal, Outokumpu |

| Package | Shrink-wrapped ,Carton boxes,Wooden pallets,Wooden boxes ,Wooden crates Etc. required. |

| Export to | India, Indonesia, Malaysia, Singapore, Saudi Arabia, Qatar, UAE, Iran, Iraq, Oman, South Africa, Nigeria, Kenya, Italy, UK, Brazil, Russia , Egypt , Kuwait , Taiwan, Australia . |

Chemical Composition

304 Stainless Strip Coils contains approximately 18% chromium and 8% nickel, with a maximum carbon content of about 0.08%. The chromium content forms a passive chromium - oxide film on the surface, which provides excellent corrosion resistance. Nickel enhances the material's ductility and toughness.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 304 | min.max. | -0.08 | -2.0 | -0.75 | -0.045 | -0.030 | 18.020.0 | - | 8.011 | -- |

Mechanical Properties

The tensile strength of 304 Stainless Strip Coils typically ranges from 515 MPa to 760 MPa. It has good yield strength, usually around 205 MPa - 210 MPa. The elongation at break can be around 40% - 60%, which means it has good ductility and can be formed into different shapes without cracking easily.

| Grade | Density | Melting Point | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||||

| 304 | 8.0 g/cm3 | 1400 °C (2550 °F) | 515 | 205 | 35 - 40 | 92 | 304 |

Physical Performance

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (μm/m/°C) | Thermal Conductivity (W/m.K) | Specific Heat 0-100°C (J/kg.K) | Electrical Resistivity (nΩ.m) | |||

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | |||||

| 304 | 8000 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 500 | 720 |

Surface Selection

Manufacturing Process

The production of 304 Stainless Steel Coil usually starts with melting the raw materials in an electric arc furnace. Then, through continuous casting, the molten metal is formed into slabs. These slabs are hot - rolled to reduce their thickness and then cold - rolled to achieve the final desired thickness and surface quality of the coil. After cold - rolling, annealing is often carried out to relieve internal stresses and improve the material's mechanical properties.

Applications

In the food and beverage industry, 304 Stainless Steel Coil is used to make food processing equipment, storage tanks, and conveyor belts due to its non - reactive and hygienic properties. In architecture, it is used for roofing, wall cladding, and handrails because of its aesthetic appeal and corrosion resistance. In the automotive and transportation sectors, it is used for exhaust systems and vehicle trim parts. It is also a popular choice for making household appliances such as refrigerators, dishwashers, and ovens due to its durability and resistance to stains and corrosion.