304 Stainless Steel Plate Description

304 stainless steel is a kind of universal stainless steel material, rust resistance than 200 series of stainless steel material is stronger. High temperature resistance is also better, can be as high as 1000-1200 degrees. 304 stainless steel has excellent corrosion resistance and good intergranular corrosion resistance. For oxidizing acids, it is concluded in the experiment that 304 stainless steel has strong corrosion resistance in nitric acid with a concentration of less than or equal to 65% of the boiling temperature. It also has good corrosion resistance to alkali solution and most organic and inorganic acids.

![]()

Chemical Composition

- Chromium (Cr): The chromium content ranges from 18.0% to 20.0%. Chromium is the key element that provides excellent corrosion resistance to the steel by forming a passive oxide layer on the surface, which protects the metal from oxidation and rusting.

- Nickel (Ni): It contains 8.0% to 10.5% nickel. Nickel enhances the corrosion resistance further and also contributes to the austenitic structure of the steel, which gives it good toughness and ductility.

- Carbon (C): The carbon content is limited to a maximum of 0.08%. This relatively low carbon content helps in maintaining good weldability and formability while still providing sufficient strength.

- Manganese (Mn): With a maximum of 2.0%, manganese helps in strengthening the steel and improving its hardenability.

- Silicon (Si): Up to 0.75% silicon is present, which acts as a deoxidizer during the steel-making process and also contributes to the strength of the steel.

- Phosphorus (P) and Sulfur (S): The maximum content of phosphorus is 0.045% and that of sulfur is 0.030%. These elements are kept at low levels to avoid brittleness and ensure good ductility.

Mechanical Properties

- Tensile Strength: The minimum tensile strength of ASTM A240 304 stainless steel sheet is 515 MPa. This indicates the maximum stress the material can withstand while being pulled apart before breaking.

- Yield Strength: It has a minimum yield strength of 205 MPa at 0.2% offset. Yield strength is the stress at which the material begins to deform plastically.

- Elongation: The elongation at break is at least 40% in 50 mm, which shows its good ductility and ability to be stretched without fracturing easily.

- Hardness: The maximum Rockwell B hardness is 92, and the maximum Brinell hardness is 201, indicating its resistance to indentation and wear.

![]()

Physical Performance

- Density: The density of ASTM A240 304 stainless steel sheet is approximately 8000 kg/m³, which is relatively high compared to some other materials, but still within an acceptable range for most applications.

- Thermal Conductivity: It has a thermal conductivity of about 16.2 W/m.K at 100°C, which means it can transfer heat relatively well compared to some other stainless steels, making it suitable for applications where heat transfer is involved.

- Coefficient of Thermal Expansion: The mean coefficient of thermal expansion is 17.2 μm/m/°C from 0°C to 100°C. This property is important to consider in applications where the material is subjected to temperature changes, as it indicates how much the material will expand or contract with temperature variations.

- Electrical Resistivity: At 100°C, the electrical resistivity is 720 nΩ.m, which affects its electrical conductivity and may be relevant in electrical or electronic applications where the material is used.

PACKING AND DELIVERY

![]()

FACTORY WORKSHOP

![]()

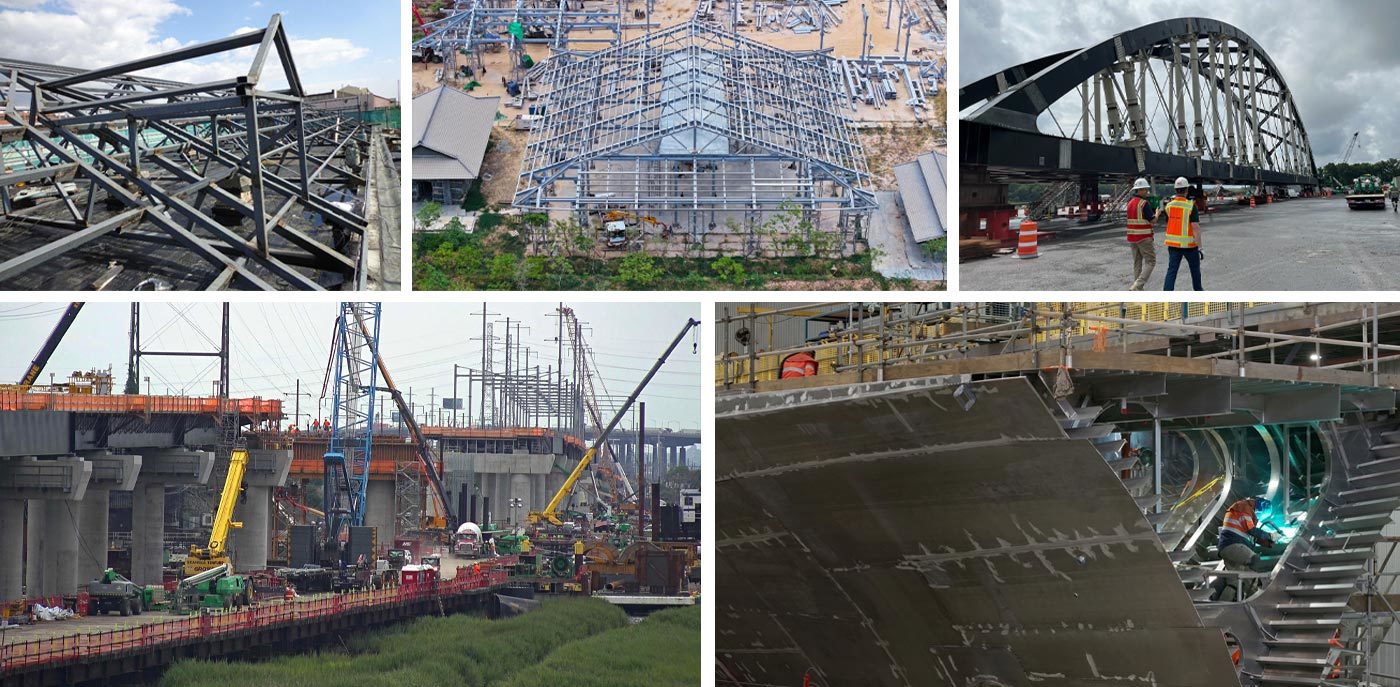

APPLICATION FIELD

![]()